With Ozoline shielding gases, productivity and a good working environment go hand in hand

Ozoline is a complete range of Messer shielding gases designed to improve the quality and productivity of almost any welding application. Due to their capacity to reduce the level of ozone in a welding area, Ozoline shielding gases provide an excellent foundation for other efforts to improve the working environment of welders and increase arc-on time.

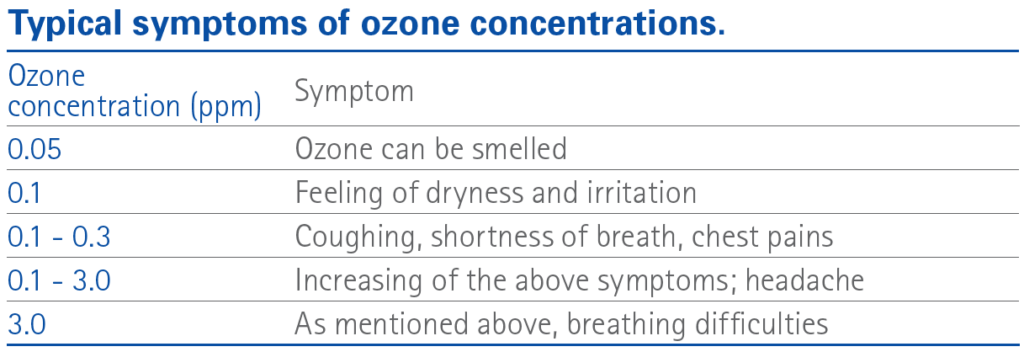

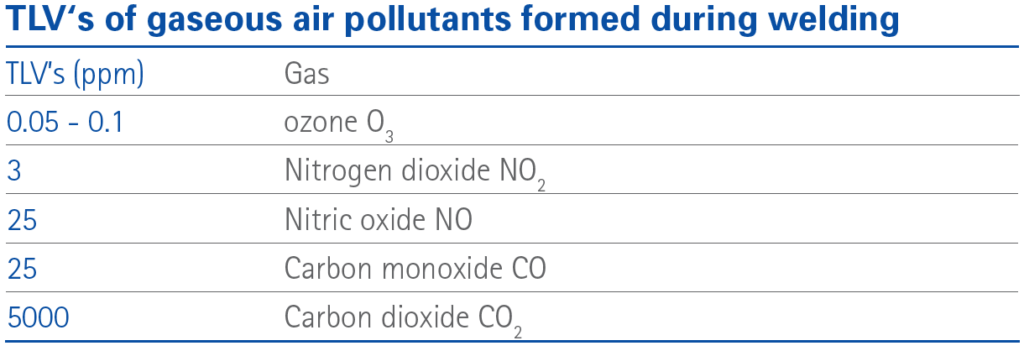

The distinctive smell of ozone is familiar to most welders. And most welders know that ozone is hazardous to their health. It causes headaches and sensations of dryness and irritation in the eyes, nose, and throat. It makes welders feel as if they’ve caught a common cold. Even very low levels of ozone have harmful effects, as the Threshold Limit Value (TLV) is very small. Even concentrations of ozone below the TLV are usually considered unpleasant, resulting in a distraction that reduces productivity. Ozoline shielding gases can lessen the amount of hazardous ozone, while at the same time improving the quality of a weld, and therefore boost productivity in more ways than one.

Ozoline – nature’s way of reducing ozone formation

The addition of a small portion of Nitric oxide (NO) to a shielding gas reduces the amount of ozone formed. The reaction between ozone and NO is natural and occurs, to a limited degree, in all welding. When the shielding gas enhances the reaction, NO readily reacts with the ozone to form Oxygen (O2) and Nitrogen dioxide (NO2). The Nitric oxide content (NO2< 300 ppm) of Ozoline gases is enough to reduce the amount of ozone formed in the welding process. The small amounts of Nitrogen dioxide produced in the enhanced welding process are a result of ozone reduction and are acceptable. The addition of NO to shielding gases does not affect the mechanical properties or the corrosion resistance of welds. In TIG and MIG welding, the NO content in the shielding gas produces a more stable and concentrated arc and which allows for a better control the welding process. This can improve the appearance and penetration profile of the weld, make positional welding easier and counteract the destabilizing effect of Helium addition often used to increase heat input.

Ozoline reduces ozone formation in most types of welding.

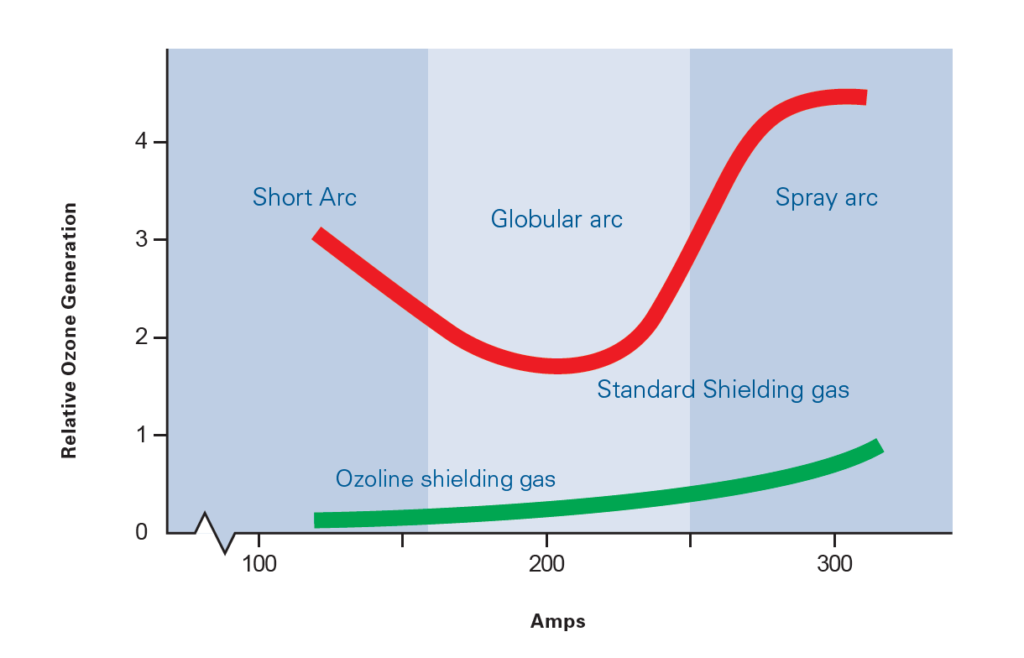

Ozoline attacks when and where ozone is formed. The nitric oxide content of Ozoline gases reacts with the ozone formed by the UV radiation emitted by the arc to form oxygen and nitrogen dioxide. The result is a significantly lower content of ozone pollutants in the welder‘s immediate area.

More on welding and a welder’s health

All welding generates hazardous pollutants in the form of fumes and gases. Their amounts produced depend on various factors, such as the welding method, the material welded, filler metal, welding parameters and the shielding gas used. Fume particles consist of metal oxides. These are formed when the melted metal is vaporized in the arc and then condenses and oxidizes upon contact with the surrounding air. The most hazardous fumes are considered to consist of Nickel and Chromium compounds that are formed during the welding of stainless steel. Ozone is one of the most dangerous and harmful gases formed during TIG and MIG-MAG welding. As a general rule, the brighter the arc and the lesser the fume production, the higher the ozone production is likely to be. Other gaseous impurities resulting from the extremely high temperatures and ultraviolet radiation emitted by the arc are Carbon monoxide (CO) and Nitrogen oxides. Most of the ozone is generated in the air layer closest to the arc, and the concentration is highest in the hot plume of fumes and gases that rise from the welding zone. The highest ozone levels are generated in the MIG welding of Aluminum. Ozone concentration in the plume is very high (4-10 ppm) as it also is in the TIG and MIG/MAG welding of stainless steels and the MAG welding of ”black“ steel.

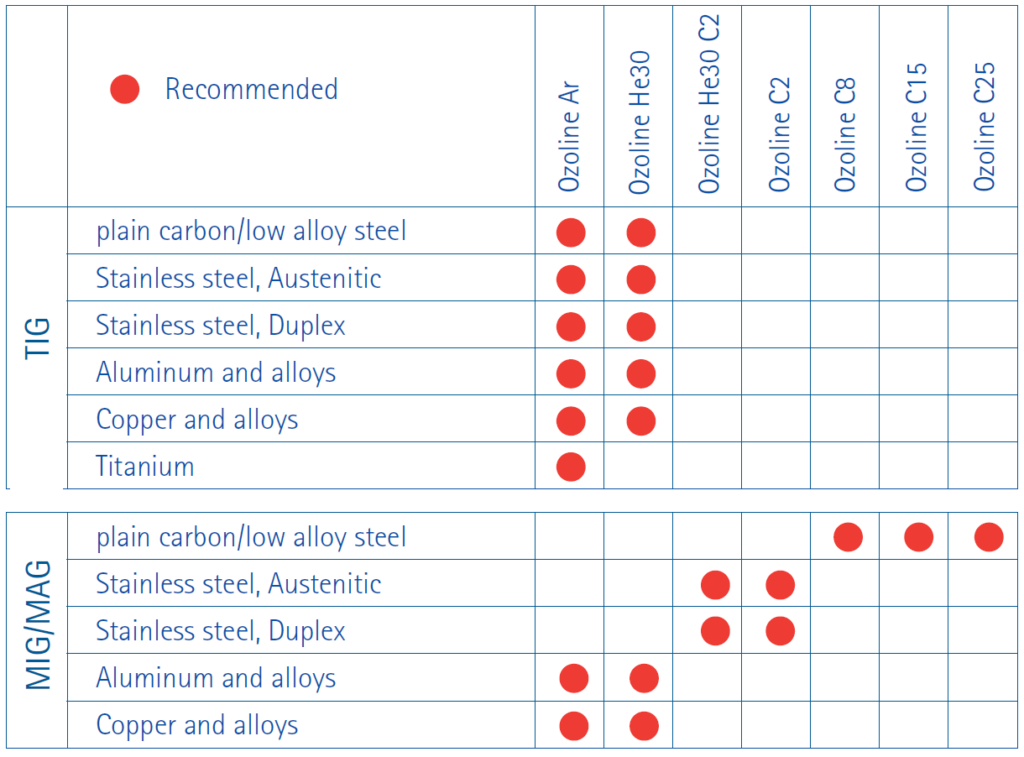

Whatever your welding needs, there’s an Ozoline shielding gas to match

Ozoline shielding gases reduce the amount of ozone formed during welding and improve a welder‘s working conditions. The addition of Nitric oxide into the shielding gas does not affect the mechanical properties or corrosion resistance of welds. In TIG and MIG welding, the NO content in the shielding gas provides a more stable arc and makes it easier to control the welding process.

-

Ozoline Ar

An all-around choice for TIG welding that provides an easy-to-strike and stable arc. For the MIG welding of Aluminum, Copper and Nickel alloys. Stable process without spatter. Excellent for the MIG brazing of galvanized steels.

-

Ozoline C25

For the MAG welding of plain carbon and low-alloy steel with solid and fluxcored wires and the welding of stainless steel with flux-cored wires. Good fluidity of the weld pool in short-arc welding.

-

Ozoline C2

An all-around gas for the MAG welding of austenitic and ferritic stainless steels, as well as for standard duplex stainless steels. For short arc, spray arc and pulsed arc. Low spatter and surface slag. Flat weld beads.

-

Ozoline He30

For the TIG welding and MIG welding of Aluminum, Copper and Nickel alloys. Helium provides an excellent fluidity of the weld pool, better penetration, higher welding speed and may reduce or eliminate the need for preheating.

-

Ozoline C8

For the MAG welding of plain carbon and low-alloy steels with solid and metal-cored wires. It’s mainly intended for spray arc and pulsed arc. Provides high welding speed, little spatter and surface slag, low weld reinforcement and efficient electrode consumption. It’s the best choice for high-productivity welding with robots and other mechanized processes.

-

Ozoline He30 C2

A high-performance gas for MAG welding of austenitic and ferritic stainless steels, as well as for standard duplex stainless steels. It is suited for all transfer modes. Low spatter and surface slag. The added Helium provides an excellent fluidity of the weld pool, improved wetting and penetration as well as higher welding speed.

-

Ozoline C15

For the MAG welding of plain carbon and low-allow steel with solid and fluxcored wires. Suitable, with certain exceptions, for pulsed welding and the welding of stainless steel with flux-cored wires. Low weld reinforcement and little spatter in all modes of arc transfer. An all-around gas for a wide variety of applications

-

Ozoline liquid

A shielding gas supplied in liquid form. It has the same properties as Ozoline Ar. Suitable for being mixed (in a mixer) with Carbon dioxide and/or Helium to form various mixtures. It makes it possible for those using liquid gas to benefit from the improvements provided by Ozoline shielding gases in their working environments.